Fiberglass blown-in insulation has grown in popularity for homeowners and constructors for numerous reasons, including its thermal performance, contribution to improved indoor air quality, and energy efficiency. If you’re experiencing extreme hot or cold temperatures driving up your utility bills, blown-in insulation may be a good solution.

Let’s dive into what you need to know about fiberglass blown-in insulation and how it can revolutionize your home’s comfort.

Defining Fiberglass Blown-in Insulation

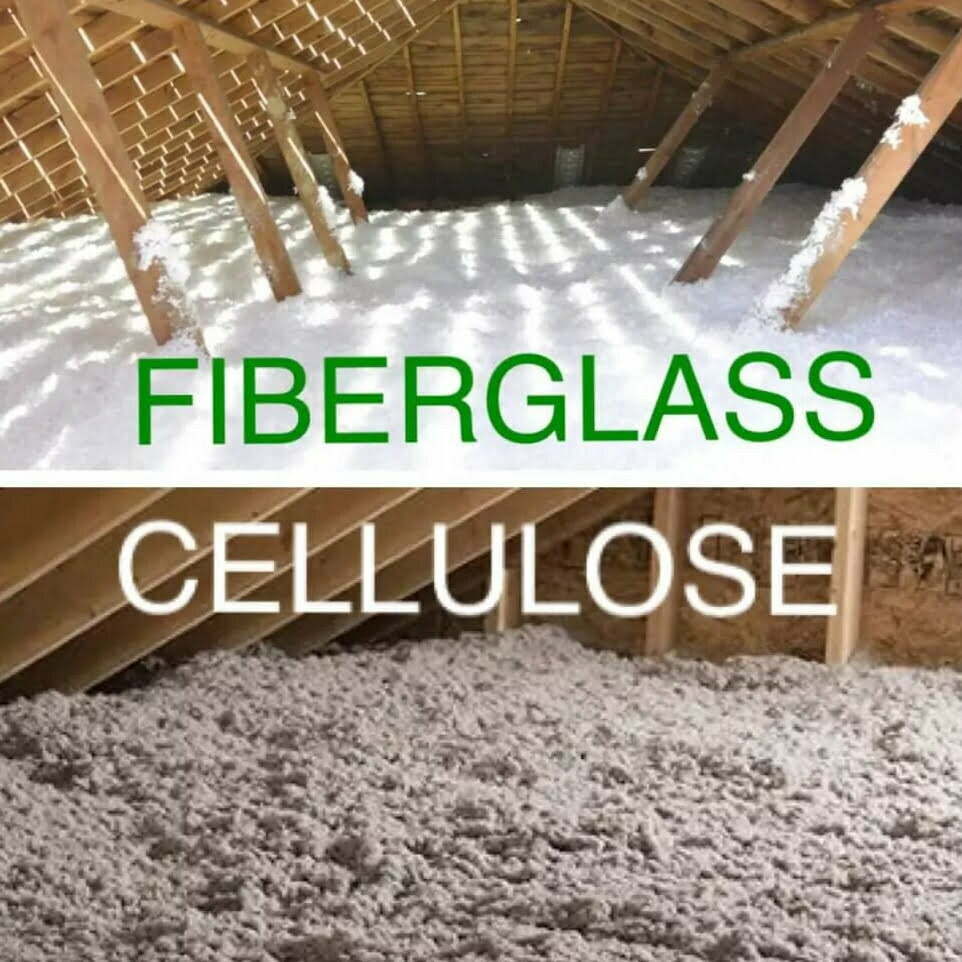

Fiberglass blown-in insulation is made from glass fibers spun into thin strands and mixed with chemicals to make the insulation fluffy and resistant to heat transfer. This insulation fills gaps and crevices in your walls or attics using these small fiberglass fragments.

The purpose of fiberglass blown-in insulation is to add higher thermal resistance to your home. In other words, it is an energy-efficient material that keeps your home warm during winter and cool in the summer.

The Process of Blowing Insulation in Your Home

Fiberglass blown-in insulation requires the expertise of insulation contractors. The process may seem straightforward but requires professional handling to ensure safety. The process looks something like this:

- Assessment and Preparation: Before beginning the installation, the installer will assess your home’s insulation needs and consider factors like the current insulation levels, the type of insulation already in place, and any areas that require special attention. Next, they will prepare the work area by ensuring it’s clean and free of obstructions.

- Safety Precautions: A professional installer will wear appropriate personal protective equipment (PPE) such as safety glasses, a dust mask, gloves, and long-sleeved clothing to protect themselves from insulation fibers.

- Drilling Access Holes: Next, access holes are drilled into the walls or ceilings, typically in the exterior or attic areas. These holes serve as entry points for the insulation material.

- Installing the Insulation: Fiberglass blown-in insulation is installed using specialized equipment, including a blowing machine. So, next in the process, a professional installer will feed the insulation material into the machine’s hopper. Then, the insulation material is blown onto the attic floor. The installer should ensure even distribution of the insulation, using the appropriate density and thickness to meet insulation requirements.

- Cleanup: The work area should be cleaned once the installation is complete. This includes removing any insulation debris, dust, or equipment from the premises.

- Post-Installation Considerations: Monitor the insulation’s performance over time to ensure it maintains your home’s energy efficiency.

As mentioned, installing blown-in insulation can be a complex task, and it’s best performed by professionals with the necessary equipment and expertise. Additionally, building codes and regulations may vary by location, so it’s advisable to consult with local authorities or professionals to ensure compliance with insulation standards in your area.

The Benefits of Fiberglass Insulation

With the installation process laid out, let’s dive into the key benefits of fiberglass insulation.

Energy Efficiency

Fiberglass blown-in insulation works by trapping pockets of air, which slows the rate of temperature change within a home. As a result, homes with this insulation tend to stay cooler in summer and warmer in winter. This reduces the need for excessive heating or cooling, thus improving energy efficiency. Blown-in fiberglass insulation also has a high R-value, allowing significantly less heat transfer and offering superior thermal performance.

Thermal Performance

In terms of thermal performance, fiberglass blown-in insulation outperforms other building materials. As mentioned, the fine fiberglass strands trap air pockets and keep them from circulating. This reduces heat transfer, maintaining a consistent temperature throughout the home. Whether it is in a chilly winter or a scorching summer, with quality insulation, your home’s indoor temperature stays comfortable without excessive use of heating or cooling systems.

Moisture Control

Moisture control plays a critical role in enhancing your home’s energy efficiency. Without proper moisture control, insulation can become damp and lose its effectiveness. Water is a conduit for heat. This means that any moisture in your insulation will expedite heat transfer, causing your HVAC system to work harder and consume more energy.

Blown-in fiberglass insulation not only provides superior thermal resistance but also has moisture-resistant properties. It can keep moisture at bay, bettering the thermal performance and the longevity of the insulation.

Improved Indoor Air Quality

Healthy indoor air quality is one of the top priorities for homeowners. Quality insulation not only provides temperature control but also helps improve the overall indoor air quality. Moisture control plays a significant role here. Excess moisture in your home can lead to multiple issues, including mold growth and an overall decrease in the air quality. Fiberglass insulation, with its superior moisture control properties, helps prevent such scenarios.

When proper insulation is combined with routine maintenance like regular duct cleaning, you can eradicate sources of contamination in your home to provide cleaner, healthier indoor air.

The Importance of Working with Professional Installers

If fiberglass insulation sounds right for you, it’s important to work with professionals. Professionals provide expert advice and ensure the insulation is installed correctly so you can reap the benefits of this material. If you’re looking for fiberglass blown-in insulation, Cincinnati RetroFoam can help.

Look to Cincinnati RetroFoam for Your Insulation Project

Since 2015, Cincinnati RetroFoam has offered premium foam insulation to homeowners that isn’t available anywhere else. Our mission is to provide impeccable service and give our best at every job to give you lasting comfort and long-term savings.

We offer a range of insulation services, including blown-in insulation, injection foam, and spray foam. We work on existing homes, new construction, pole barns, and commercial properties. Whatever your insulation needs are, we’re here for you. We also offer financing options if you’re looking for ways to manage insulation costs. Let us serve as your trusted partner for your upcoming insulation project. Contact us today to get your free quote.

Frequently Asked Questions

What is the life expectancy of blown-in fiberglass insulation?

Blown-in fiberglass insulation can last 20-30 years, depending on your attic’s existing ventilation. Insulation experts can help determine the existing ventilation for you and make recommendations for the best insulation for your home.

How Does Fiberglass Insulation Contribute to Sound Insulation?

Fiberglass insulation can help absorb and reduce sound levels. However open-cell spray foam in RetroFoam injection foam is the preferred material for sound-deadening.

How Does Installing Fiberglass Insulation Result in Home Improvement?

Improving your home’s energy efficiency, comfort, and sustainability are all integral parts of home improvement – and fiberglass insulation contributes significantly to all these aspects. The energy efficiency of a home is greatly improved with the installation of adequate insulation. It reduces the workload on your heating and cooling systems, thereby increasing their lifespan. Plus, it leads to lower energy consumption, reducing your utility bills.