Whether your home has existing insulation that needs to be updated or you’re looking to insulate your walls to improve energy efficiency, injection foam is a reliable solution. Injection RetroFoam insulation is the best solution on the market for effective wall insulation. Let’s dive into what you need to know about this insulation and how it works.

What is Injection Wall Foam Insulation?

Injection wall foam insulation refers to installing liquid foam insulation into the hollow cavities of exterior and interior walls. Unlike traditional fiberglass batt insulation that is manually inserted, injection foam insulation utilizes special equipment to mix and inject foam insulation to fill every nook and cranny. The liquid foam insulation adheres to the studs and other surfaces to create a seamless barrier resistant to airflow and moisture.

Benefits of Injection Wall Foam Insulation

Choosing to upgrade the insulation in your home’s walls with injection foam offers several advantages compared to traditional insulation materials and methods.

Improved Insulation and Energy Efficiency

The main benefit of injection foam insulation is enhanced thermal performance. The cell structure of cured foam blocks heat transfer through the walls, increasing the R-value (thermal resistance). With an R-value around R4.6- to R-5 per inch, RetroFoam’s R-Value actually goes up as it gets colder. Studies have shown that fiberglass starts to lose its R-Value at 32 degrees, while RetroFoam’s R-Value goes up to R-5 at 30 degrees. By minimizing heat loss in winter and heat gain in summer, injection foam insulation can significantly reduce energy usage and costs.

Air Sealing and Draft Blocking

Unlike fiberglass insulation, which leaves gaps for airflow, injection foam insulation works to seal off any cracks, holes, and penetrations. This sealing prevents conditioned air from escaping and unconditioned outdoor air from entering the home.

Sealing drafts and air leaks can save you up to 30% on energy bills yearly. By cutting down on air infiltration, injection foam insulation improves comfort and indoor air quality and provides energy savings.

Noise Reduction

The dense structure of cured injection foam also dampens sound transmission through walls. They fill the cavities with foam insulation to block exterior noise, such as traffic from entering the home. Rooms insulated with injection foam are noticeably quieter.

Moisture Resistance

Injection foam insulation offers excellent resistance to moisture absorption and can block liquid water and water vapor. By preventing moisture intrusion, injection foam helps protect against mold, mildew, rotting walls, and structural damage. It adds a water-resistant barrier to the home.

How Injection Wall Foam Insulation Works

Installing injection foam insulation requires specialized equipment and proper training for correct installation. Here is an overview of the injection wall foam insulation process:

Overview of the Injection Process

The liquid chemical components that make up the foam are kept under pressure and must be heated to the proper temperatures during installation. The applicator uses a proportioning pump that mixes the two components in the correct ratio through heated hoses.

As the mixture exits the spray nozzle inside the wall cavity, the chemicals react and rapidly grow, sticking to all surfaces to fill voids.

Foam Fills Cracks and Gaps

One of the key benefits of the injection process is that the liquid foam can flow into even the smallest spaces inside wall cavities. The foam will find its way into corners, around wires, between studs, and through cracks. This ensures complete insulation coverage without gaps or air pockets.

Creates a Seamless Air Barrier

Unlike installing fiberglass batts by hand, which often results in compression and gaps, injection foam insulation adheres and seals to create a seamless, continuous layer of insulation and air sealing in the wall cavity. There are no seams or cracks for air leakage, delivering superior thermal performance and energy efficiency.

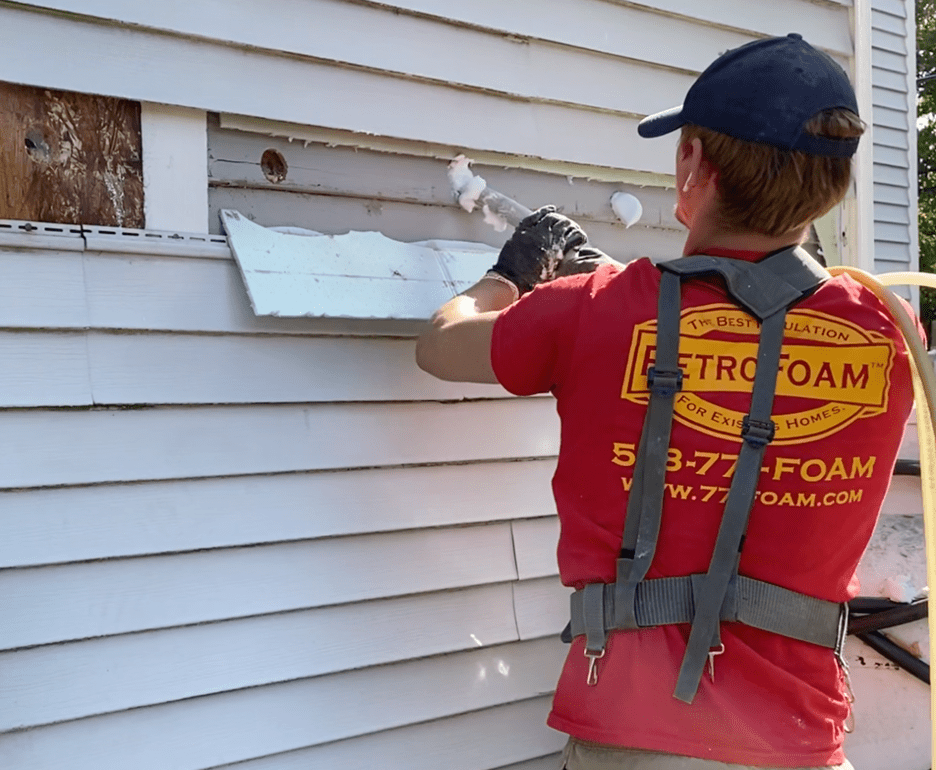

Retrofitting Existing Walls

One of the biggest advantages of injection foam insulation is the ability to retrofit it into existing homes. After drilling access holes between wall studs, the foam can be pumped into cavities that already have fiberglass batts, improving insulation levels and air sealing. No demolition is required.

Insulate Your Home with Cincinnati RetroFoam

Since 2015, Cincinnati RetroFoam has provided superior insulation services that aren’t offered elsewhere. If you’re looking to insulate walls with injection foam or you want to insulate another part of your home, we are your trusted guide. In addition to injection foam, we offer blown-in and spray foam insulation. We work on existing homes, new construction, pole barns, and commercial properties. Let us help you insulate your space to provide years of lasting comfort. Contact us today for your free quote.

Frequently Asked Questions

Does injection foam insulation require removing existing insulation?

In most retrofit cases, injection foam can be applied on top of existing insulation without removal. Small access holes are drilled into the wall cavities so the foam can fill in gaps and enhance insulation levels.

Is the installation process disruptive?

For retrofit projects, most of the work can be done from the interior by drilling access holes between wall studs. This results in very little disruption to siding, drywall, or existing materials. The injection process itself is quick and clean.