Spray foam insulation has become an increasingly popular choice among homeowners looking to insulate their houses. With its ability to air seal, provide moisture resistance, and deliver a high R-value per inch, spray foam offers unique advantages that help keep your home comfortable.

What is Spray Foam Insulation?

Spray foam insulation is a two-part liquid foam insulation material sprayed in place to insulate and air-seal spaces. The liquid starts as two separate components – isocyanate and polyol resin – that are kept in separate containers.

During installation, these two liquids are pumped to the spray gun nozzle where they combine and chemically react, expanding and curing into foam plastic. The resulting foam quickly adheres and conforms to the shape of any surface or cavity it is sprayed into. After full curing, it hardens into rigid plastic foam filled with tiny air cells.

This cellular structure is what gives spray foam its insulative properties. The air trapped within the cells slows down heat transfer and convection. The expanding foam seals these openings when sprayed into cracks, gaps, and spaces, stopping air infiltration and leakage.

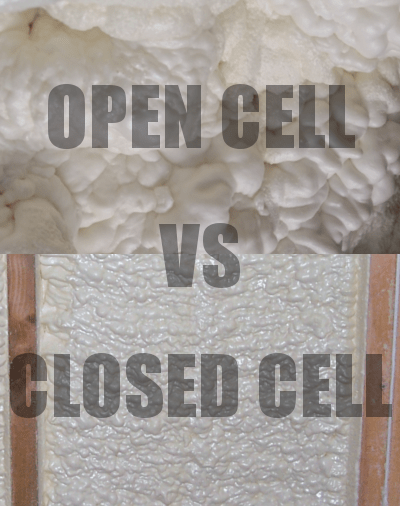

There are two main types of spray foam insulation: open and closed-cell.

Open-Cell Spray Foam

Open-cell spray foam has a density of approximately 0.5 pounds per cubic foot. The cells within the foam are not completely closed but instead interconnected, giving the foam a spongy, permeable structure. This allows for some air movement through the foam. Open-cell foam expands approximately 100 times its liquid volume when sprayed.

Open-cell foam has an R-value of between R3.5 to R4.5 per inch, and it is known for its moisture-absorbent properties. It’s also less expensive than closed-cell foam.

Open-cell spray foam acts as an air barrier but not a vapor barrier. It provides good insulation and sealing against small air gaps and cracks.

Closed-Cell Spray Foam

Closed-cell spray foam has a higher density of approximately 2 pounds per cubic foot. Its compact cellular structure gives it increased rigidity and resistance to air and moisture flow. Closed-cell foam expands approximately 30-60 times its liquid volume when installed.

The small, closed cells of closed-cell foam block moisture and air infiltration more effectively than open-cell foam. Closed-cell spray foam has an R-value of R6 to R7.4 per inch, providing very high insulating power. It also provides structural enhancement due to its rigidity.

Closed-cell foam qualifies as a vapor barrier given its resistance to vapor transmission. The tight polymer chains and high density make closed-cell foam resistant to the absorption of liquid water as well.

The Benefits of Spray Foam House Insulation

There are several key reasons why installing spray foam has become popular among homeowners and builders looking to insulate and air-seal properties:

Higher R-Value per Inch

The R-value indicates an insulating material’s ability to resist conductive heat transfer. The higher the R-value, the better the product resists heat flow and conducts less heat. This means more effective insulation and energy efficiency.

Most traditional insulation materials such as fiberglass batts and cellulose insulation have an R-value between R-3 to R-4 per inch. Standard extruded polystyrene rigid foam boards provide around R5 per inch. Closed-cell spray foam, however, can offer an R-value of R6 to R7.4, depending on where you get your insulation.

This higher R-value allows specified insulation levels to be achieved with a thinner application. This benefit is useful in retrofit applications where space for adding insulation may be limited.

Air Sealing Ability

Air leakage accounts for up to 40% of energy loss from buildings. Drafts, air gaps around windows or doors, and other unsealed areas allow conditioned indoor air to escape while letting outdoor air infiltrate in. This not only increases energy consumption but also makes indoor spaces uncomfortable.

Spray foam completely fills any gaps, cracks, or spaces it is sprayed into. As it expands, the foam adheres to surrounding surfaces and substrates, forming an airtight seal that stops infiltration or exfiltration. This greatly enhances the energy efficiency of the building envelope, resulting in heating and cooling cost savings of 10-20% or more. Air sealing also minimizes drafts, humidity, and condensation issues.

Moisture and Mold Resistance

Spray foam insulation provides excellent resistance against moisture and condensation problems within building assemblies. Closed-cell spray foam in particular forms a vapor-impermeable barrier due to its dense structure and cellular composition.

The tight matrix of cells resists the absorption of liquid water. Properly applied closed-cell foam prevents moisture from passing through exterior walls, ceilings, and floors. This minimizes the chances of moisture issues, mold growth, and rot within the building structure.

In flood zones, closed-cell spray foam can help prevent water intrusion and soakage into walls. The dense foam helps strengthen structural assemblies against water damage as well.

Customizable Installation

One of the key advantages of spray foam insulation is that it expands and adheres to fill any shape or space. The liquid foam can reach into nooks, corners, angular joist cavities, and other areas that traditional rigid insulation boards would be unable to fit into.

After installation, the cured foam conforms exactly to all surrounding surfaces, completely filling gaps and sealing any air spaces. This allows insulation of very complex or irregularly shaped assemblies. Spray foam insulation can be applied to a wide range of depths within cavities. Installers can adjust the thickness and coverage per project requirements to achieve specified R-values.

This versatility and customizability make spray foam an ideal insulation solution for unique architectural designs and building structures. It is also well-suited for adding insulation to existing finished spaces during home improvement projects.

Long-Term Performance

Spray foam insulation provides durable long-term performance as an air barrier and thermal insulator. The foam bonds tightly to surrounding substrates, framing, and surfaces after curing. And since it seals out water and vapor, the insulation is protected from moisture degradation within wall and ceiling cavities.

Where to Use Spray Foam in Your Home

Given the application method, performance attributes, and benefits, there are three areas in particular where spray foam insulation excels:

1. Attics/Roof Lines

Applying spray foam insulation to attic floors, sloped ceilings, and roof rafters provides complete thermal separation between the attic and living spaces. Foam applied to the underside of roof decking seals off attic eaves and rafters, preventing heat loss through these areas.

Spray foam also air seals any gaps around attic hatches, recessed lights, electrical boxes, plumbing vents, and more. This stops conditioned indoor air from escaping to the attic and causing moisture issues like ice dams.

Cathedral ceilings and knee wall attic spaces also benefit from spray foam insulation. The liquid foam easily adheres to any angled or sloped surfaces, insulating irregular framing configurations. The airtight seal minimizes condensation buildup within these notoriously difficult areas to insulate and properly ventilate.

2. Exposed Foundation Walls

Applying spray foam to foundation walls in unfinished basements or crawl spaces provides excellent thermal and moisture protection. The foam both insulates, and air seals the porous concrete or cinder block foundation. This seals out drafts and moisture penetration through the foundation.

In cold climates, this converts drafty, uninsulated basements into warmer, more comfortable spaces. The insulation helps moderate basement interior temperature fluctuations as well. Open-cell foam generally works for most applications, while closed-cell foam provides maximum moisture resistance.

3. Rim Joists

Rim joists are prone to significant air leakage and heat transfer issues. These horizontal boards connect a home’s outer wall vertical framing to the floor joists. The gap between the floor joists and the rim joist cavity allows air infiltration.

Spray foam applied to the rim joist cavities adheres tightly to all surrounding surfaces. This foams in any gaps around electrical or plumbing within the joists as well. A proper rim joist spray foam application stops costly air leakage in this weak spot.

Look to Cincinnati RetroFoam for Your Insulation Needs

Whether your home needs spray foam insulation to fill exposed walls or an attic, or you’re seeking another insulation solution, Cincinnati RetroFoam can help. Since 2015, we’ve provided outstanding insulation services not found anywhere else. In addition to spray foam, we offer blown-in and injection foam services. We can work on existing homes, new construction, commercial properties, and pole barns. Request your quote today to get started.

Frequently Asked Questions

Does spray foam require removing drywall?

RetroFoam injection foam can be applied directly through small holes drilled into the drywall at strategic points. The foam then expands to fill the wall or ceiling cavity without major demolition.

For new construction, the foam is sprayed onto the interior side of the wall sheathing before the drywall goes up. No tear-out should be required.

Can spray foam be removed or replaced?

Removing cured spray foam is extremely difficult and usually requires rebuilding the entire assembly. Spray foam is intended as a permanent insulation and air barrier solution.

What is spray foam insulation cost?

Spray foam cost can vary depending on many factors, such as your current insulation, how big your space is, and if the job requires special work to reach the location (such as with hard-to-reach areas). The best way to determine the labor costs is to request a quote.